General

VZERO ENGINEERING SOLUTIONS SL informs the users, through this notice, you can use cookies when the user navigates through the different screens and pages of the site.

While using our site you agree and expressly authorizes the use of cookies in accordance with our Privacy Policy.

What are cookies?

A cookie is a small text file that a Web server can store on the hard disk of a computer to store some information about the user. The cookie identifies your computer uniquely, and can only be read by the Web site that sent the team.

A cookie is not an executable file or a program and therefore can not propagate nor contain a virus or other malicious software, and can not be longer than 4000 characters.

What are cookies?

A "cookie" is a small text file that is stored on your computer's hard drive and which records your navigation of a website (if you allow) so that, when you revisit that website, it can present tailored options based on the information stored about your last visit. Cookies can also be used to analyse traffic and for advertising and marketing purposes. Cookies identify the computer biunivocally and can only be read by the website that sent it to the computer.

Cookies are not executable files or programs do not contain viruses or malware and cannot have a length greater than 4000 characters. Cookies are used by nearly all websites and do not harm your system.

What are cookies used for?

Usage of cookies aims at recalling user preferences (language, country, log in, internet browser features, information on the use of our webpage, etc.)

Recalling your preferences prevents us, for example, of asking you about your country of origin everytime your visit our webpage. We will be aware of the features your operating system and the browser of the device in use and therefore we will be able to offer you a better navigation experience.

Cookies may help our website to distinguish user’s browser as a previous visitor and thus store and recall the established preferences during navigation, customize homepage , identify which sections of the web have been visited or keeping a selections register as for example in an “add-to-cart”.

Vzero Engineering Solutions, S.L. may employ the cookies with the aim to recognize the users who have accessed our website and be able to offer them a better and more customized service. Additionally, cookies may be used to obtain information on the date and last time of user’s visit, measure some traffic parameters within the site and estimate the number of visits received, so that Vzero Engineering Solutions may focus and adjust promotions and services more effectively.

Usually, websites employ cookies to obtain statistical information about their webpages. Bear in mind that we gather data related to your navigation in our web as statistical data, not personal.

Types of cookies

Cookies may be classified according to the entity managing them, their persistence time or their aim. In some occasions a cookie is included in more than one category.

Ownership

- Own cookies (first party cookies): are those sent to user’s device from a devide or domain managed by Vzero Engineering Solutions S.L..

- Third party cookies: are those sent to user’s device from a device or domain not managed by the editor, but by another entitiy which processes the obtained data through cookies.

Persistence time

- Session cookies: are those which gather data while the user is navigating the webpage.

- Persistent cookies: are those in which data are stored in the device and can be accessed and processed during a definite period by the cookie responsable. These times may range from a few minutes to years.

Aim

- Technical cookies: are those used internally and required for the proper functioning of the webpage.

- Analytic cookies: are those which allow to collect statistical information on the user’s activity. Such information is gathered anonymously and allows to optimize the navigation in our website with the finality of providing a better service to the user.

- Customization cookies: are those which allow the user Access the web service with some general features predefined as a function of some criteria in the user’s device as for example: language, browser type, regional configuration, etc.

- Advertising cookies: are those which allow the management, in the most efficient way of the advertising spaces that the editor may have included in the webpage, application or platform from which the service is offered according to criteria such as edited contents or the frequency with which advertisements are shown.

- Behavioral advertisement cookies: are those which allow for the management, in the most efficient way, of the advertising spaces that the editor may have included in te webpage, application or platform from which the service is offered. These cookies store information of the behavior of the users obtained by means of the continued observation of their navigation patterns, which allows for the development of an specific profile to show publicity accordingly.

Aim of the cookies

In what follows a list of the cookies that can be found in our webpage is presented together with a brief description of their aim. We hereby ensure that none of them keeps personal information identification about the users. Some cookies customize your experience, some recall your preferences whilst others only give us statistics about visitors.

|

Cookie

|

Descripción

|

Duración

|

Fuente

|

|

__utma

|

Visitors identification: used to register visitors with statistical and analytical aims

|

2 years

|

Google

(Analytic)

|

|

__utmb

|

Determination of visitor’s sesión: Google Analytics uses two cookies to establish ne session. If one of them is missing another activity initiates the new session.

|

30 minutes

|

Google

(Analytic)

|

|

__utmc

|

Determination of visitor’s sesión: Google Analytics uses two cookies to establish ne session. If one of them is missing another activity initiates the new session.

|

Session

|

Google

(Analytic)

|

|

__utmz

|

Register of traffic sources and navigation: Employed to record how you reached our website (Google search, advice, etc) and the trajectory you follow while navigating our site. We use this information to improve user’s experience in future updates.

|

6 months

|

Google

(Analytic)

|

Protection safeguards.

The user may configure his/her browser to accept or not the cookies which receives or to allow the browser to advice when a server wishes to store or delete a cookie from his/her device. In case of having accepted third parties’ cookies and wishing to retire consentment on the same, the user can find instructions in the security configuration of his/her browser.

Examples:

- If you use Microsoft Internet Explorer, on the Tools menu> Internet Options> Privacy> Settings.

- If you use Firefox, the menu item Tools> Options> Privacy> Cookies.

- If you use Google Chrome in the menu Settings> Privacy

- If you use Safari on the menu Preferences> Security

- If you use Ópera: Configuration>Remove personal information.

- If you use a native explorer in your phone, Settings> Remove data or Privacity and Security*

* May vary depending on the model or version of operating system.

You may make use of the “Help” section that you will find on the tools menu of most browsers to change your computer settings, however, some of the features of our online services may not work or may result more complicated to Access if all the cookies are rejected.

Many browsers allow to activate a private mode with which the cookies are always deleted after your visit. Depending on the browser thisprivate mode may be named in different ways. Below you can find a list of the most common browsers and the names of the private mode.

- Internet Explorer 8 and higher versions: InPrivate

- FireFox 3.5 and higher versions: Private Navigation

- Google Chrome 10 and higher versions: Incognito

- Safari 2 and higher versions: Private navigation

- Opera 10.5 and higher versions: Private navigation

- Browser: Incognito tab.

Please, read carefully the help section of your browser to know more about how to activate the “Private Mode”. You will still be able to visit our webpage, nevertheless, the user’s experience may not be optimal and some features may not work properly.

Additionally, you can also manage the cookies storage in your browser by means of tools like:

- Ghostery: www.ghostery.com/

- Your online choices: www.youronlinechoices.com/es/

Vzero Engineering Solutions S.L. thanks you for the activating cookies acceptance; this helps us to obtain more precise data which allow us to improve the content and the design of our webpage to adapt it to your preferences.

In addition, Vzero Engineering Solutions S.L., is present in web portals and third-parties services. If you wish to know the privacy conditions and cookies usage conditions of these sites you will need to consult the policies provided by them:

- Facebook: https://es-es.facebook.com/help/cookies

- Twitter: https://twitter.com/privacy

- YouTube: https://www.google.es/intl/es/policies/technologies/cookies/

- LinkedIn: http://www.linkedin.com/legal/privacy-policy

- Google+: https://www.google.es/intl/es/policies/technologies/cookies/

- Instagram: https://www.instagram.com/legal/cookies/

Protection safeguards.

It is possible that we update the Cookies Policy of our website. For that purpose, we recommend you to review this policy everytime that you access our webpage, with the aim to be adequately informed on how and what we use cookies for.

The period of conservation of data obtained for the different aims established in the article 13.2 a) of General Data Protection Law and in relationship with the rest of the information required in the abovementioned article, is accounted for in our Privacy Policy.

Aerospace technology has typically marked the pace for the development of the rest of technologies. It is a fact that systems from this industry have experienced a continuous and fast evolution during the last 100 years.

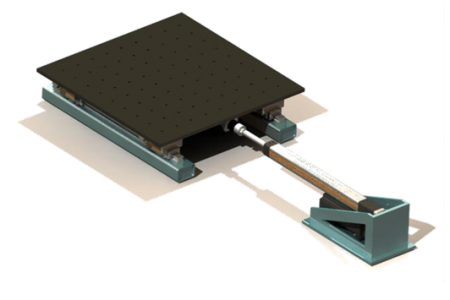

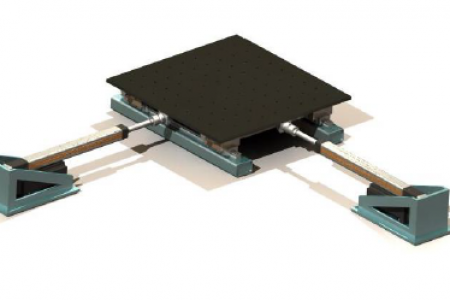

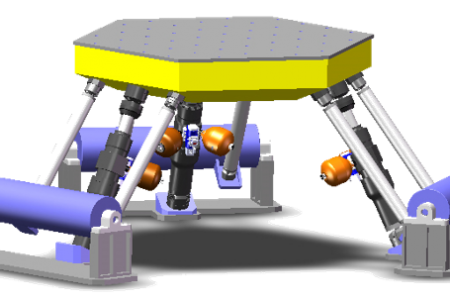

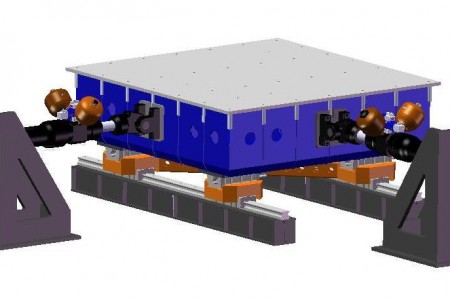

Aerospace technology has typically marked the pace for the development of the rest of technologies. It is a fact that systems from this industry have experienced a continuous and fast evolution during the last 100 years. Dynamic Structural Testing Systems for fatigue, durability. These typically comprise servoactuators, hydraulic power unit, hydraulic service manifolds, control system, reaction frames and load application tooling.

Dynamic Structural Testing Systems for fatigue, durability. These typically comprise servoactuators, hydraulic power unit, hydraulic service manifolds, control system, reaction frames and load application tooling. Components: Servoactuators, controllers, hydraulic power units, hydraulic service manifolds, reaction frames, etc.

Components: Servoactuators, controllers, hydraulic power units, hydraulic service manifolds, reaction frames, etc.